You will be able to:

Tag: battery

Cellution Corporate Presentation

Please review our corporate presentation to learn more about our services and background information regarding stationary energy storage.

Download: Cellution Company Introduction (English)

Webinar: Design and Operation of Industrial Battery Storage

New Webinar Available: Design and Operation of Industrial Battery Storage

Introduction

The webinar “Design and Operation of Industrial Battery Storage” is organised by Cellution, Consulting and Engineering for Energy Storage. It will be hosted by Leon Gosh (Cellution, CEO), an experienced system engineer and consultant, specialised in stationary battery systems with experience in R&D and field application.

The webinar gives you a general introduction into different energy storage technologies but is focused on electrochemical (battery) storage. It covers a broad variety of topics like market, applications, project development, design and operation.

Key Aspects

- Understand different types of storage technologies

- Perform a technical and economical assessment

- Execute design and planning tasks for energy storage projects

Content

The content of this webinars divided in four parts and consists of the following topics:

- Applications of Stationary Electrical Energy Storage Systems

- Technology Development, Cost and Market Growth

- Life Cycle Phases

- Performance Indicators

- Lead Acid Batteries

- Redox Flow Batteries

- Li-Ion Batteries

- Economical Assessment

- Design Process

Why Participate?

The design and operation of a utility-scale battery storage system is for many companies new territory and definitely linked to many new challenges. Especially for companies that are not well experienced in the field of battery storage, we are offering a webinar to provide an introduction. This webinar will enable you and your colleagues to work with battery storage, to develop projects and to perform technical as well as economic assessment.

The workshop in person was already held in three different countries (Germany, Spain and Cambodia) on two different continents (Europe and Asia). For further information about the workshop and other services of Cellution, please contact Leon Gosh.

Register Now

Please note: Due to technical restrictions the available places on this webinar are limited.Reserve your spot now and sign in to the webinar early to ensure your participation.

Please note: The webinar will be held via Zoom.

For more information please contact us or visit our website on www.cellutionenergy.com.

More Information and RegistrationFire Protection for Li-Ion Batteries

The fire risks of a Li-Ion battery system due to their high potential fire load have to be handled with great care. However with the right measures the risk can be reduced and a safe operation be ensured. They best way to prevent a fire from happening is an early detection of gaseous electrolyte and an inerting of the battery room with e.g. nitrogen or carbon dioxide. This procedure is described and recommended by Siemens in a published white paper form January 2019. Siemens offers as well the fire protection equipment as the FDA241 air sampling detector in combination with the Sinorix N2 extinguishing system.

Cellution offers a risk analysis regarding the fire risks of a Li-Ion battery system as well as a fire protection concept. Please feel free to get in contact with us for details.

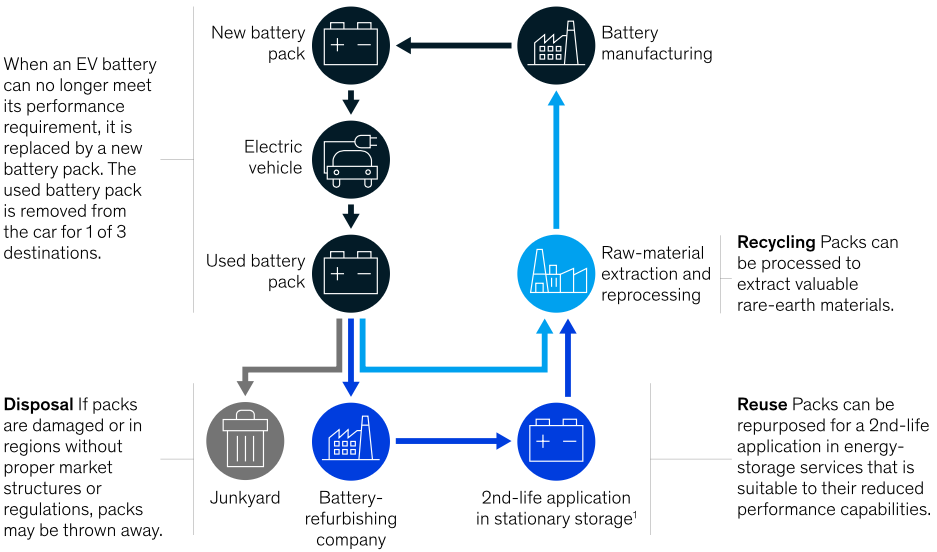

2nd Life Application for EV Batteries

As you may know, Li-Ion batteries loose their capacity (kWh) over their lifetime. At a certain point this means for electrical vehicles, that the range (km), which depends on the battery capacity, is not sufficient anymore. This happens after approximately 5-10 years operation, depending on the behavior of the car owner. What happens with the battery of an electric vehicle after reaching this point? There are three different possible scenarios: disposal, recycling or reuse. The disposal is the most common method and results in a simple combustion of the batter, which is of course not a sustainable use of raw material and neither is it good for the environment. The second option is recycling, where the raw material like cobalt, nickel or manganese is extracted and reprocessed. The third option is to reuse the batteries and give them a 2ndlife.

The batteries after operation in an electric vehicle may have not enough capacity left to satisfy the requirements of transportation but may are still suitable for other applications. This could be e.g. frequency response for the electricity grid or a back up system for a data center. These are stationary applications, which require many battery packs of electric vehicles connected in series and parallel to form a so called utility-scale battery system. Different OEMs like Daimler or Nissan are already working with used EV batteries to develop 2ndlife applications.

The volumes of used EV batteries will be huge in the future with the growing amount of EVs in Europe. This amount can even overcome the amount of new installed stationary utility-scale batteries by 2030.

Despite the huge potential of 2ndlife EV batteries there are as well challenges to overcome like regulations for used battery applications or standards for the development of battery packs, as every OEM has their own battery pack design. Despite that already battery manufacturers are developing different cells for EV and stationary applications (as well called “ESS – Energy Storage System”). This makes totally sense as cells for EV need a high energy density and a lifetime of ~1000 cycles, which results in ~300 000km. Cells for stationary applications need a lifetime of more than ~4000 cycles to realize a feasible business case and the energy density is not as critical as for mobile applications.

2ndlife will definitely be an application that will find its place in the stationary market for a certain duration and is a very good alternative to a direct disposal. But in my opinion in the future the battery packs for EV will be designed for a shorter lifetime to fit the requirements for the this particular applications and afterwards go to a recycling process to extract the raw material. For stationary applications different cells are being developed and with decreasing battery prices the purchase of new batteries will be more economical rather than using the EV batteries after their first end of life.

Please find below an article regarding this topic from McKinsey, which shows most of the aspects discussed above more in detail.

Link to article by McKinsey

Recycling of Li-Ion Batteries

Worldwide more than 5% of all Li-Ion batteries are being recycled. This low amount is due to the fact that recycling of Li-Ion batteries as today is not an economical feasible business case. Even though raw material prices raise in the past years (especially Cobalt) but still there is no break even point reached in this process. Additionally the responsibility for the disposal or recycling is shifted from the battery manufacturer to buyers in Europe. This is an important point in the negotiation with a battery manufacturer that should be looked at closer and not be forgotten in a n economical analysis of the whole lifetime of a battery system.

In the future due to new recycling methods more batteries surely will be recycled and hopefully we will reach 100% recycle rate one day. According to an article of energy-storage.news and a Canada-based recycler a 100% recycle rate of Li-Ion batteries is achievable.

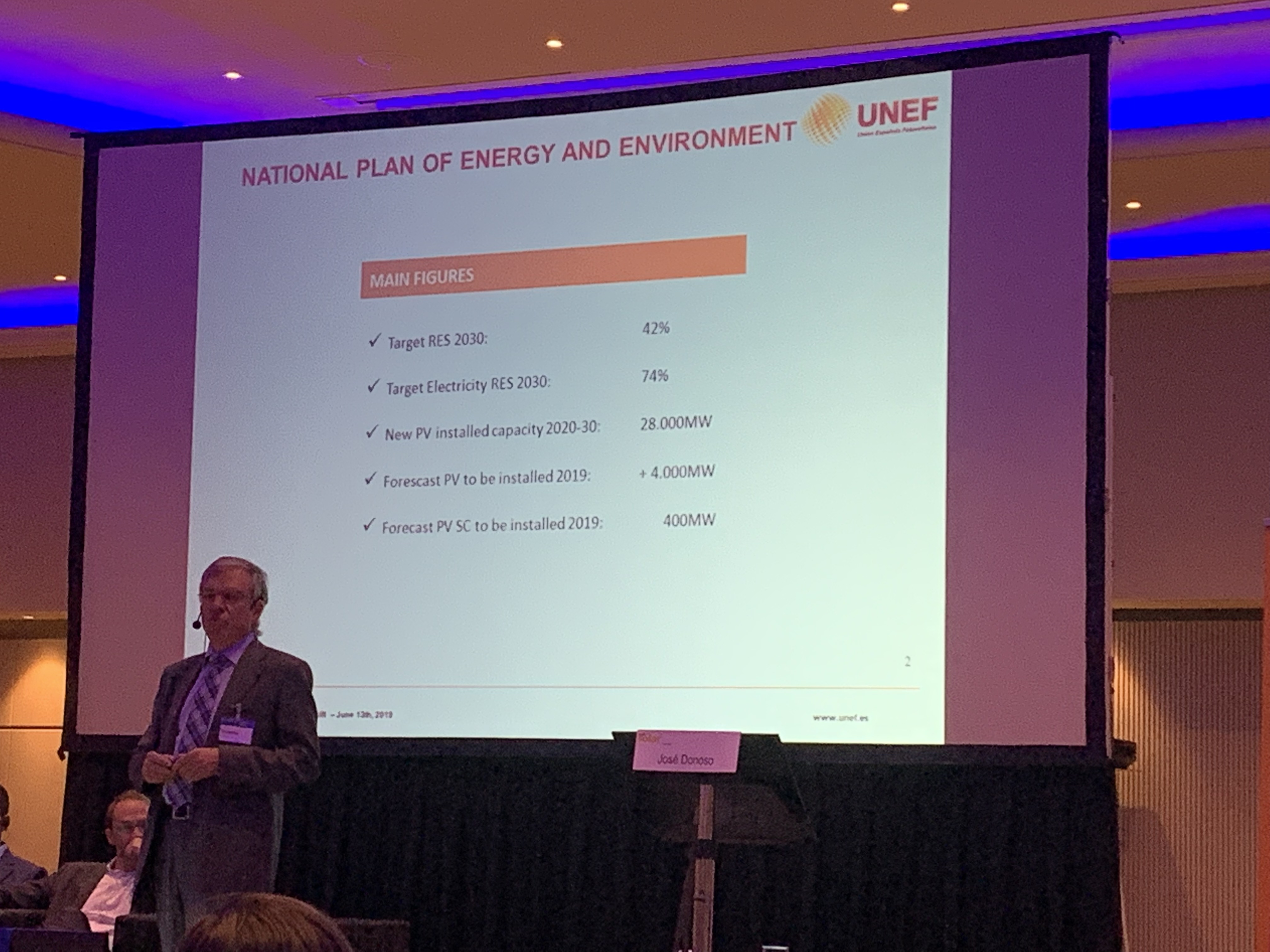

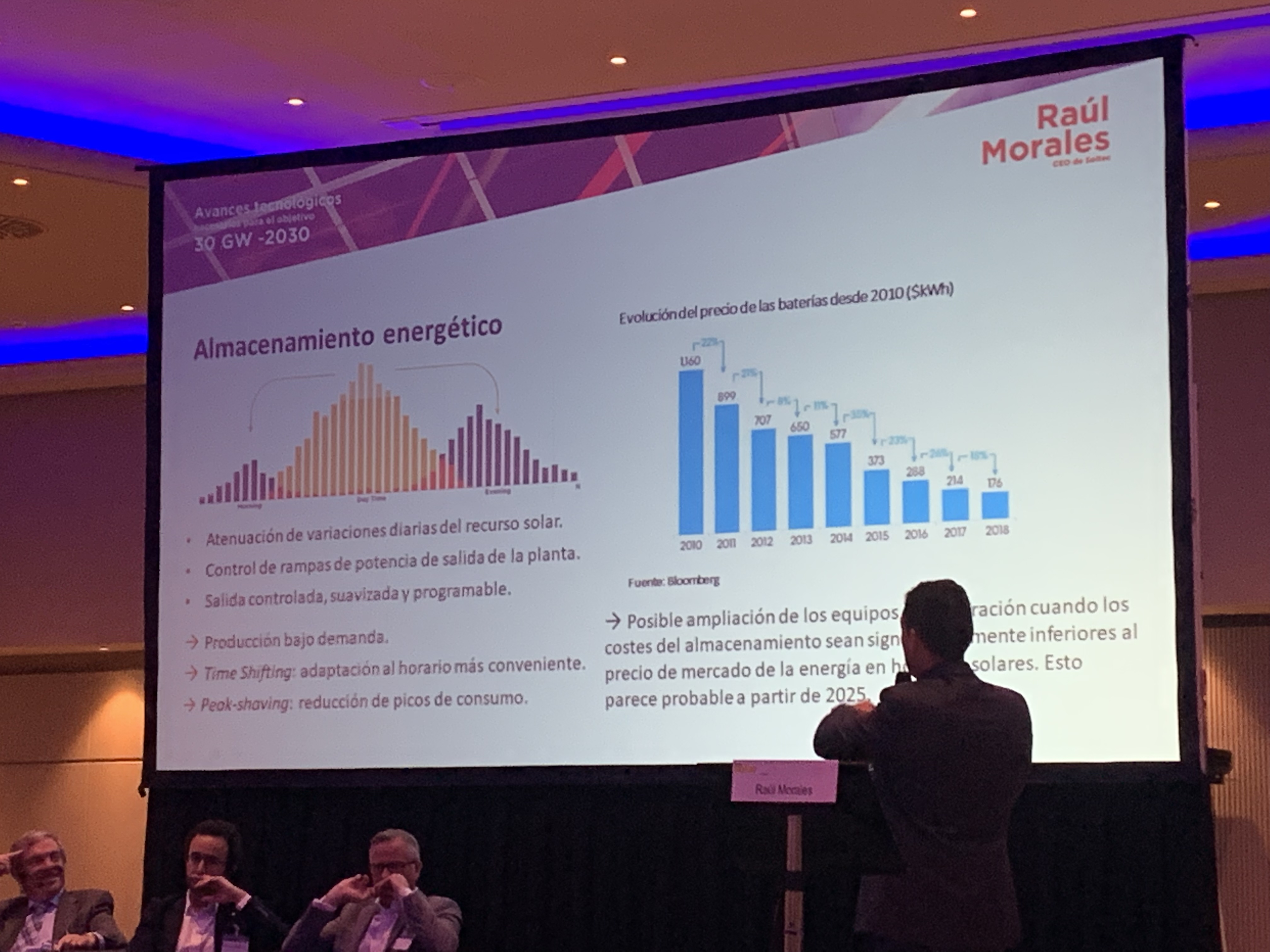

Intersolar Summit Spain 2019 – Solar Growth in Spain brings New Opportunities for Energy Storage

At the Intersolar Summit Spain 2019 in Barcelona this week on the 18th of June the Solar community got together and discussed the national plan for energy and environment. This plan includes the target of Spain having 74% renewable electricity supply in 2030 which will include new PV installation of 28GW from 2020 to 2030. This means an installation of 2800MW of Solar in average each year from 2020 to 2030. Compared with the installation in 2018 of roughly 260MW this will be a huge increase for the next 10 years in Spain.

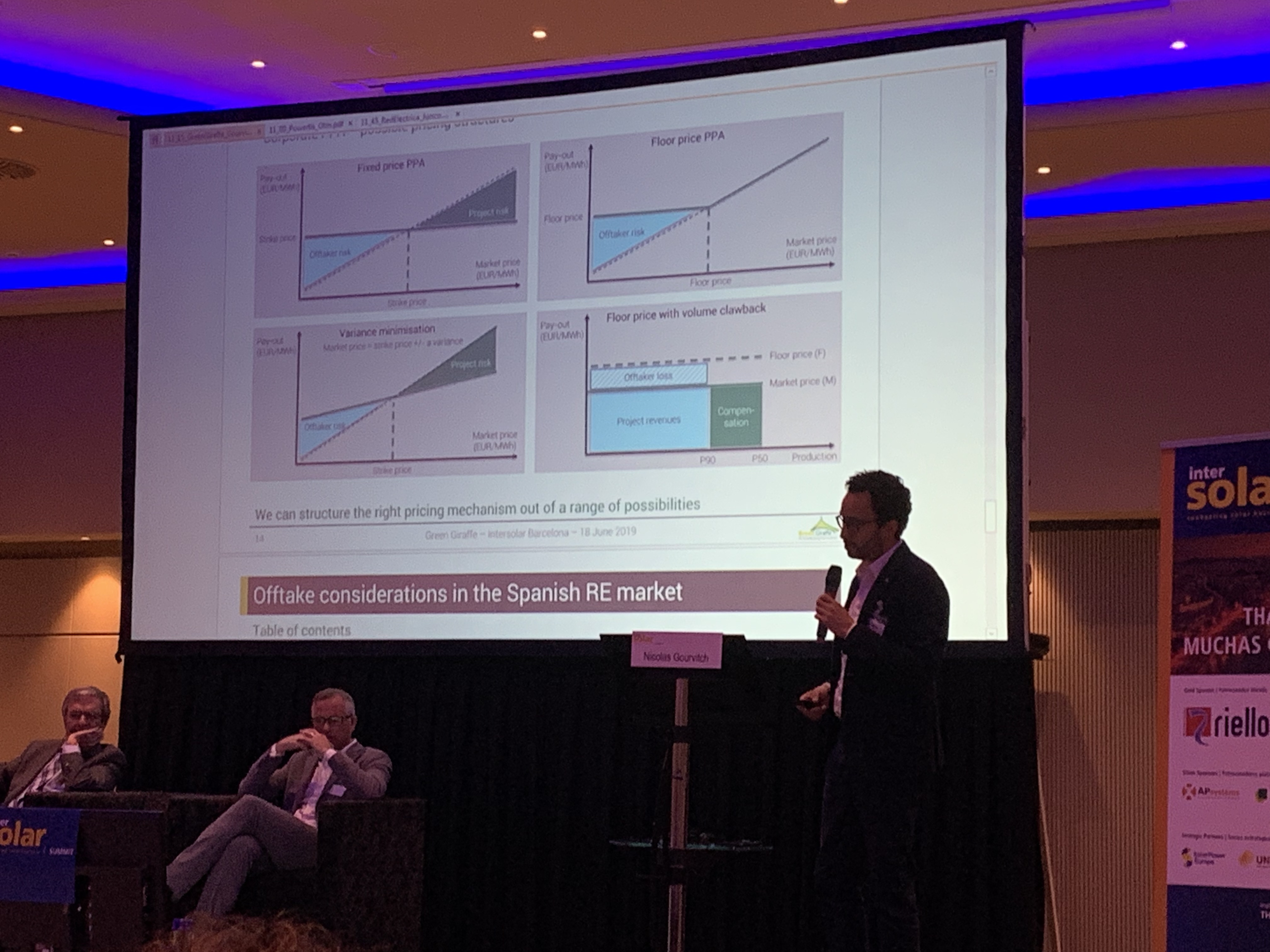

Most Common Business Model – PPA

Together with increased PV installation the opportunities for energy storage will rise. In Spain are great opportunities for Power Purchase Agreements (PPAs) according to Bruce Douglas, Deputy CEO and COO at SolarPower Europe. Within a PPA most commonly a price for the electricity purchase is fixed over a certain duration. But as presented within the Intersolar Summit there are many different possibilities for PPAs as presented by Nicolas Gourvitch (Founder of Green Giraffe).

Opportunities for Energy Storage – Merchant and Energy Shifting

Merchant

For example, together with PPAs, energy storage can bring benefit to Solar energy providers by storing energy in case the electricity price at EEX (European Energy Exchange AG) is lower than the contracted PPA price. This energy can be traded at the EEX in case the current price index is above the contracted PPA price. This is just one example for an application of a battery system combined with PV.

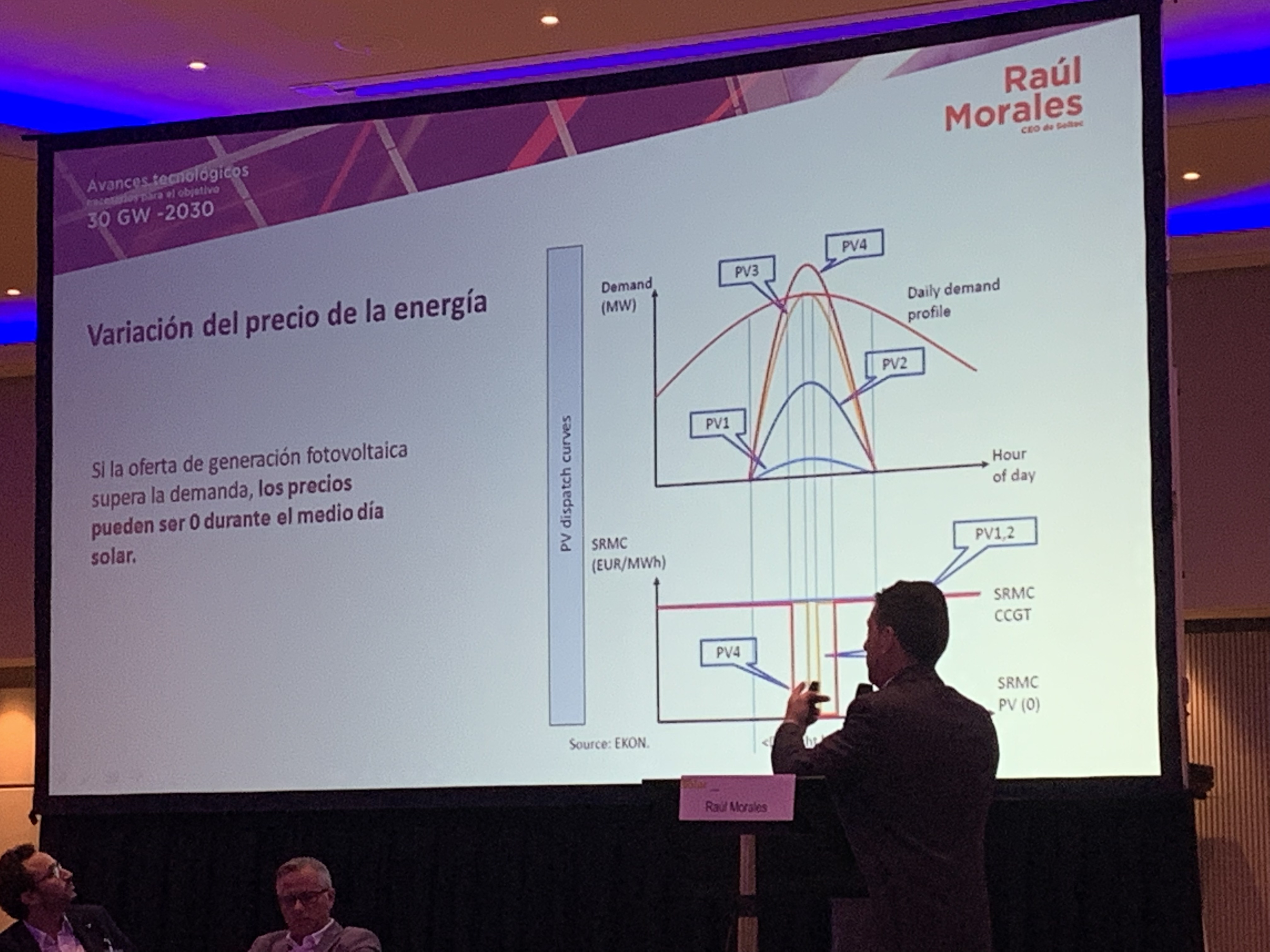

Energy Shifting

According to Raúl Morales (CEO at Soltec) there will be an overproduction of Solar energy during the midday, which results in an electricity price of zero or even negative values. This scenario will get more and more important with the raise of Solar power and brings huge potential for energy shifting with storage solutions like batteries. This statement was backed up by the Spanish TSO Red Eléctrica (presented by Paula Junco, Tecnico de la Dirección de Operacioines) for the winter months. There is a big potential for energy shifting although in the summer months the solar power will match the electricity demand in the near future.

Cellution at Intersolar Summit Spain 2019 in Barcelona at June 18th

Cellution will be at the Intersolar Summit Spain 2019 in Barcelona!

Spains solar market is reignited and this leads to big opportunities for the combination with battery storage.

From 2017 to 2018 Spain nearly doubled its yearly new installed solar capacity from 135MW to 262MW. This increase is driven by lower production costs and cancellation of fees and charges such as the sun tax. If you participate at the Intersolar Summit in Barcelona on 18.06.2019 then I would be glad to meet you there!

Find more information about the Intersolar Summit Spain here.

Wind + Storage in Germany

Wind + Storage in Germany is not an easy business case at the moment to develop. Projects like the one below from EWE only work due to big investment from the Japanese Organization NEDO (New Energy and Industrial Technology Development Organization). In case the production of electricity by the wind park is too high for the grid or the prices at the stock are negative, the operator has to turn down the power or even completely shut the whole wind park down. The problem is that the operator gets paid the whole amount he lost due to being prevented to produce electricity. This regulation erases one major benefit a combination with energy storage would offer. Nevertheless cellution is working with wind project developers in Germany on the development of economical feasible business models that combine a broad variety of revenue streams a battery can offer to a wind park. Get in contact with us to discuss opportunities for wind+storage in Europe and we will support you during the evaluation of the business case.

O&M in Energy Storage

Operation and Maintenance is a critical factor in energy storage systems as availability is key to a successful business model and often required by contractual circumstances with customers or grid operators. Not only is non-availability lowering the revenue of a plant, it can as well causing liquidated damages or even harm business relationships on a ling term.

An battery energy storage system is complex and consists of many parts which in total requires a interdisciplinary team to cover all upcoming problems during O&M. From my time at Vattenfall in the maintenance of conventional power plants I experienced that the maintenance is limited nowadays to reactive maintenance. When a part has a failure, the asset manager reacts and mostly replace the part. In case of battery systems this methodology will not succeed on a long term as availability is a crucial factor. Here we will experience the advantages of predictive maintenance with machine learning and big data analysis to lear more about battery operational behavior and failure prediction.

Read an interesting article from energy-storage.news here

Solar needs storage to compete in National Grid’s UK Capacity Market redesign

National Grid has outlined how renewables could participate in the UK’s Capacity Market, unveiling technology-specific de-rating factors that range from 1–15%.

However National Grid’s Daniel Burke warned that there remains a long way to go before renewables can participate in CM auctions, not least because of the need for policy reform.

Any introduction of renewable energy into the CM would require regulatory overhaul from BEIS and market regulator Ofgem, matters which, Burke said, mean it is “quite feasible” to “take some time”.

Recent Comments